Optimisation of the oxygen use in EAF steelmaking by direct process monitoring of the chemical melt reactions (OxyMon)

EU Research Fund for Coal and Steel (RFCS)

Technical Group 2: “Steelmaking Processes”

Initial situation:

The EAF has a high demand on electric and chemical energy for melting scrap. In the EAF chemical energy is applied in different ways:

- by oxygen injection through bottom nozzles to decarburise the melt,

- by oxygen-natural gas burners during melting phase and

- by oxygen jets to decarburise the melt, to promote slag foaming in combination with carbon injection and for post combustion.

All these contributions are hard to separate, thus the individual influence on the overall furnace performance and the efficiency of the different oxygen sources is difficult to determine and to optimise.

Objectives of the project are to:

- investigate metallurgical reactions by injection of oxygen gas in the liquid steel bath,

- optimise the use of oxygen at the bottom nozzle, as well as oxygen jets and gas burners,

- determine optimal carbon additions to diminish iron oxidation,

- and thus to optimise the efficiency of chemical energy input while maximising productivity and resource efficiency and minimising maintenance effort.

Ways and means:

To investigate and to optimise the efficiency of the different chemical energy sources, dedicated measurement and modelling tools are used:

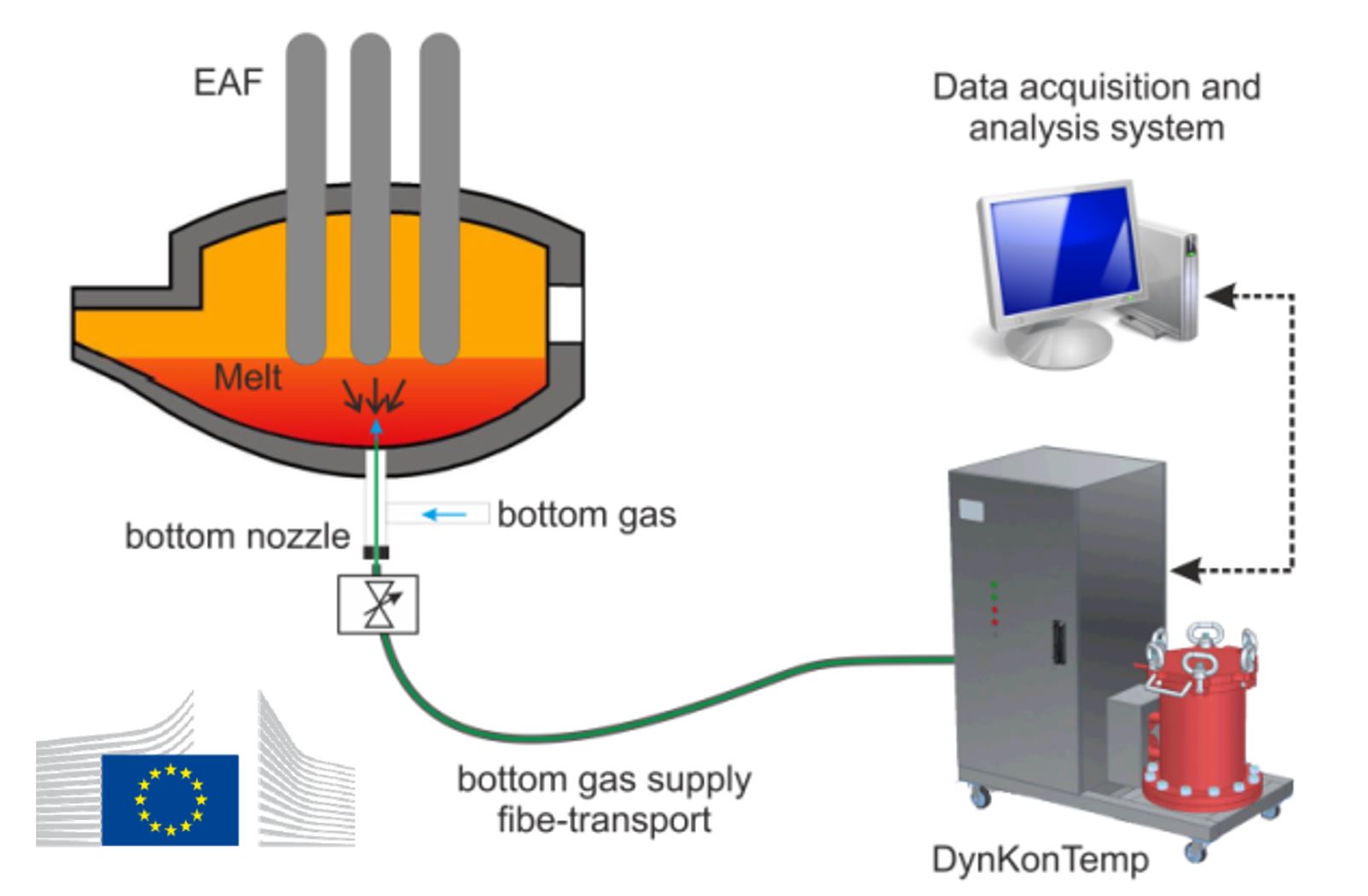

- A local fibre optical liquid steel temperature measurement will be applied to measure the hot spot temperature of oxygen blowing directly in the process. This will be used to monitor in-situ the effect of relevant metallurgical reactions as decarburisation and metal oxidation on the local melt temperature. (MINKON DynTemp®)

- A detailed multi zone reaction model on the basis of thermodynamic and kinetic calculations will be developed to estimate the energy contribution and efficiency of the individual chemical reactions. (KTH)

- A dynamic process model will be enhanced to calculate from a mass and energy balance based on cyclic process data the time evolution of the mean melt temperature and the oxidation status with carbon and oxygen content based on more precise and individual input. (BFI)

Members of consortium

Coordinator:

- MINKON SP ZOO, Poland

Partners:

- VDEH-BETRIEBSFORSCHUNGSINSTITUT GMBH, Germany

- FERRIERE NORD SPA, Italy

- KUNGLIGA TEKNISKA HOEGSKOLAN, Sweden

Main contact:

Mark Potter, Minkon Sp. z o.o, UL Nakielska 42/44, 42-600 Tarnowskie Gory, Poland, Phone: +48 32 381 42 21, email: Mark.Potter@minkon.pl

Acknowledgement:

The project leading to this application has received funding from the

Research Fund for Coal and Steel under grant agreement No 754064”.

For more information on the Minkon Dyntemp System please follow link below.

http://www.minkon-international.com/products-and-technology/steelplant-consumables/#dyntemp-fibre-optic-temperature-measurement-system